Joinery

For my midterm project for Subtraction, I wanted to construct the case for a desktop vending machine for the battery store that I run with Lindsey Daniels. I’ve seen pictures of this done before, but the creator doesn’t release his plans since he sells the parts on his website. Why not make my own?

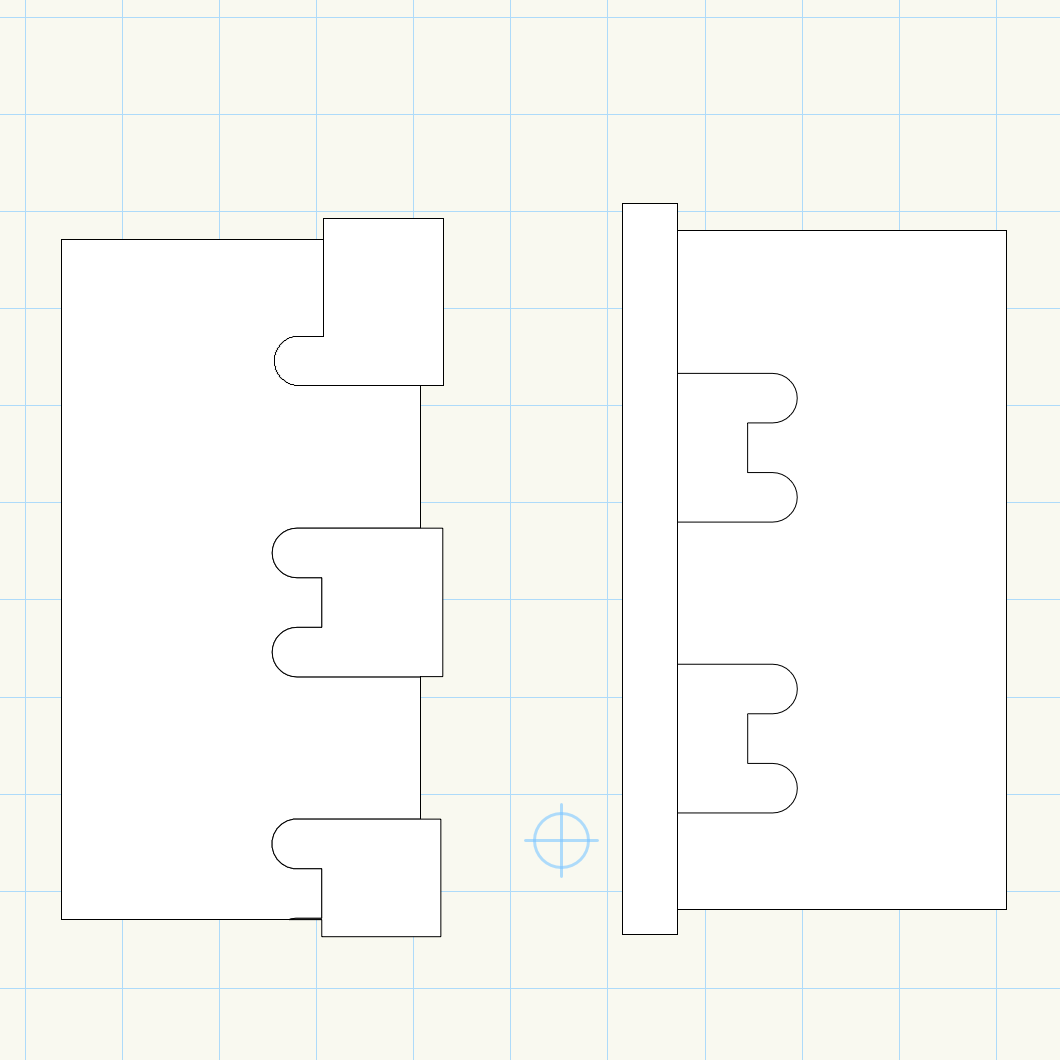

Consequently, the joints I needed to study are tenons– I’ll be making use of a lot of right angles for the vending machine. It was a little tricky making the template in vector works, and I got frustrated more than a few times. I never really understood when and why the program would want to snap things, so I often had to manually adjust x and y coordinates.

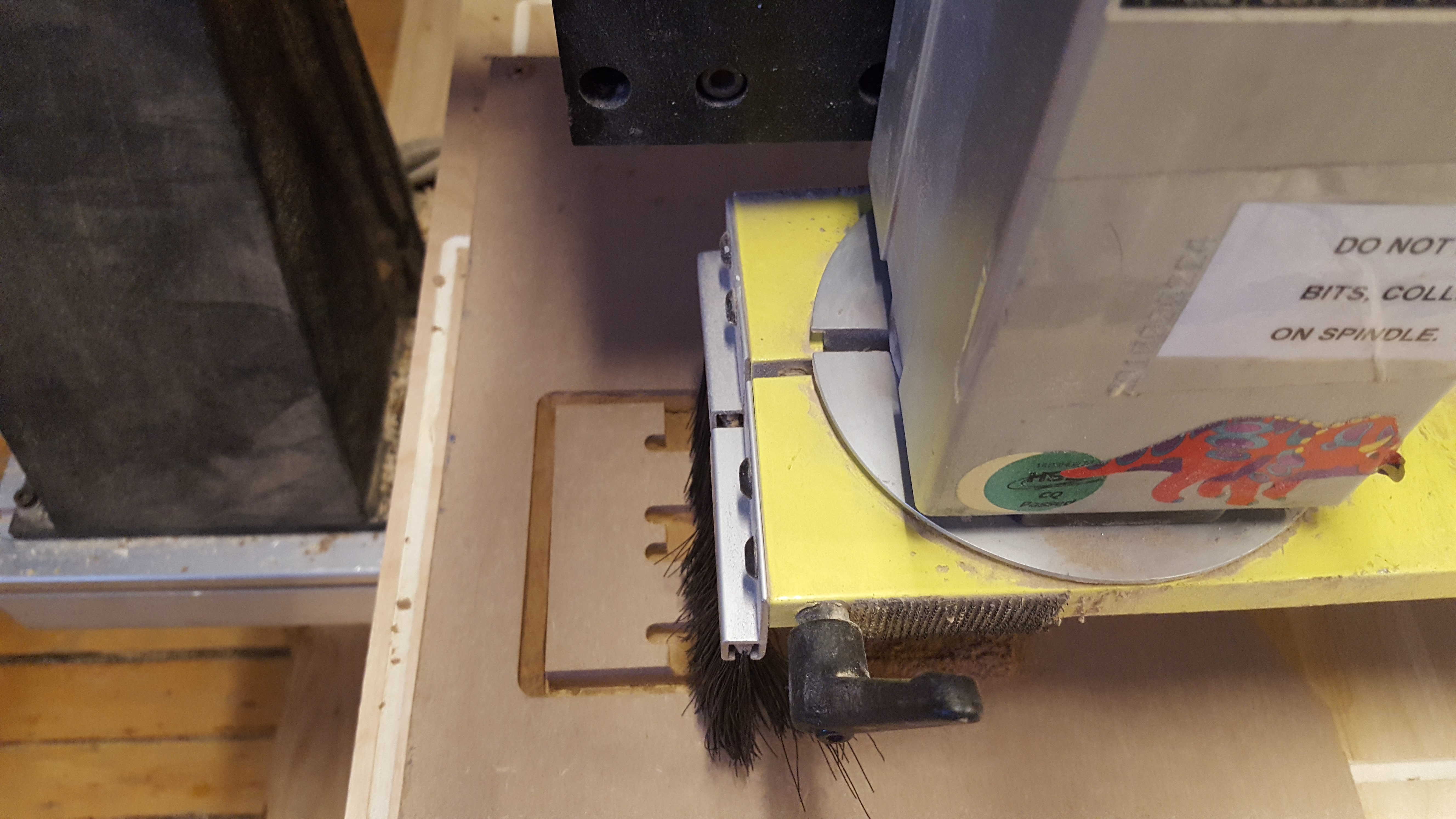

After this, cutting was a bit of a cinch. I was working off the scraps of my MDF last week, so I was a bit concerned about the spacing, but it worked out fairly well.

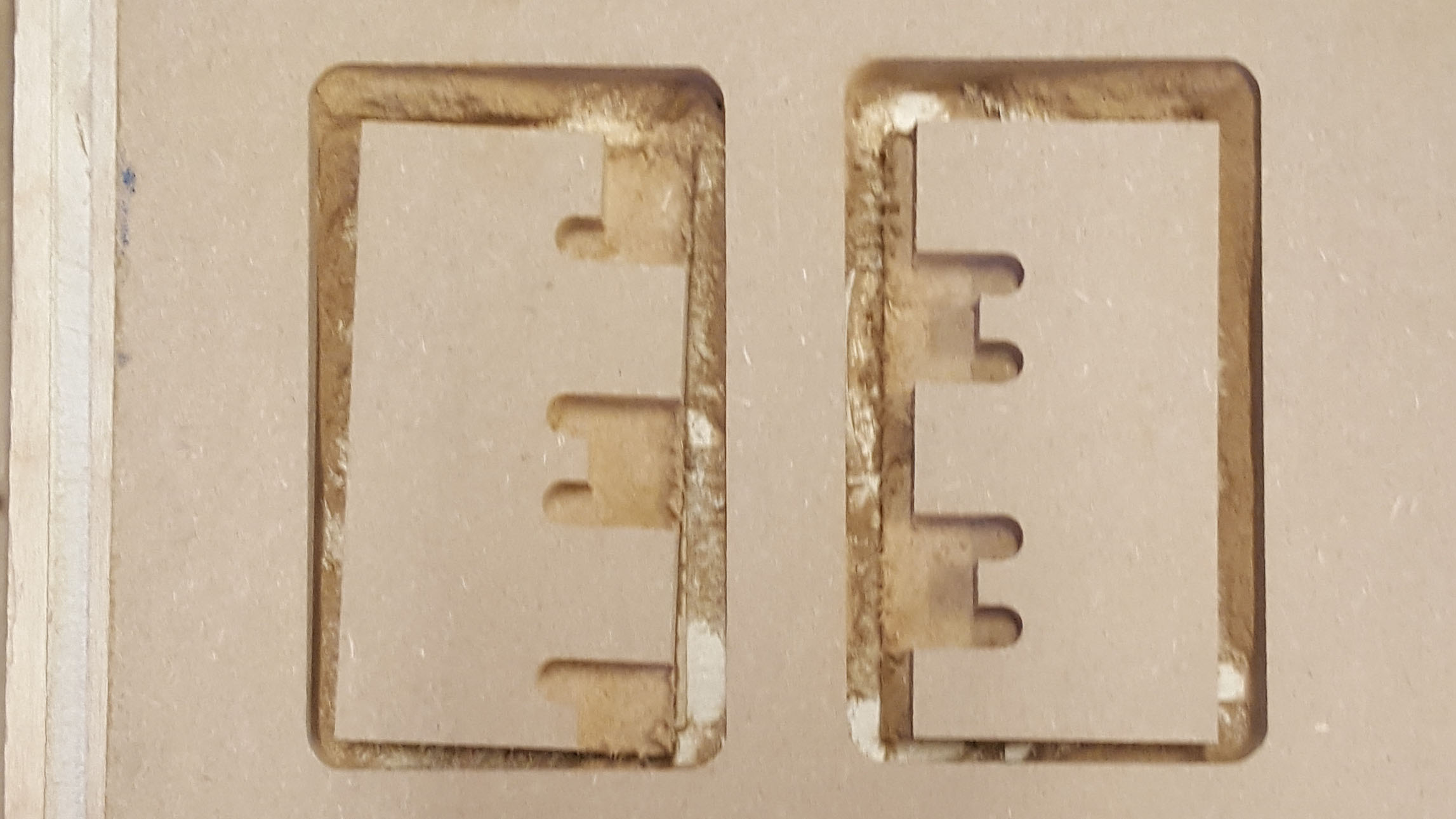

They’re very little, but they’re important for testing this joint out!

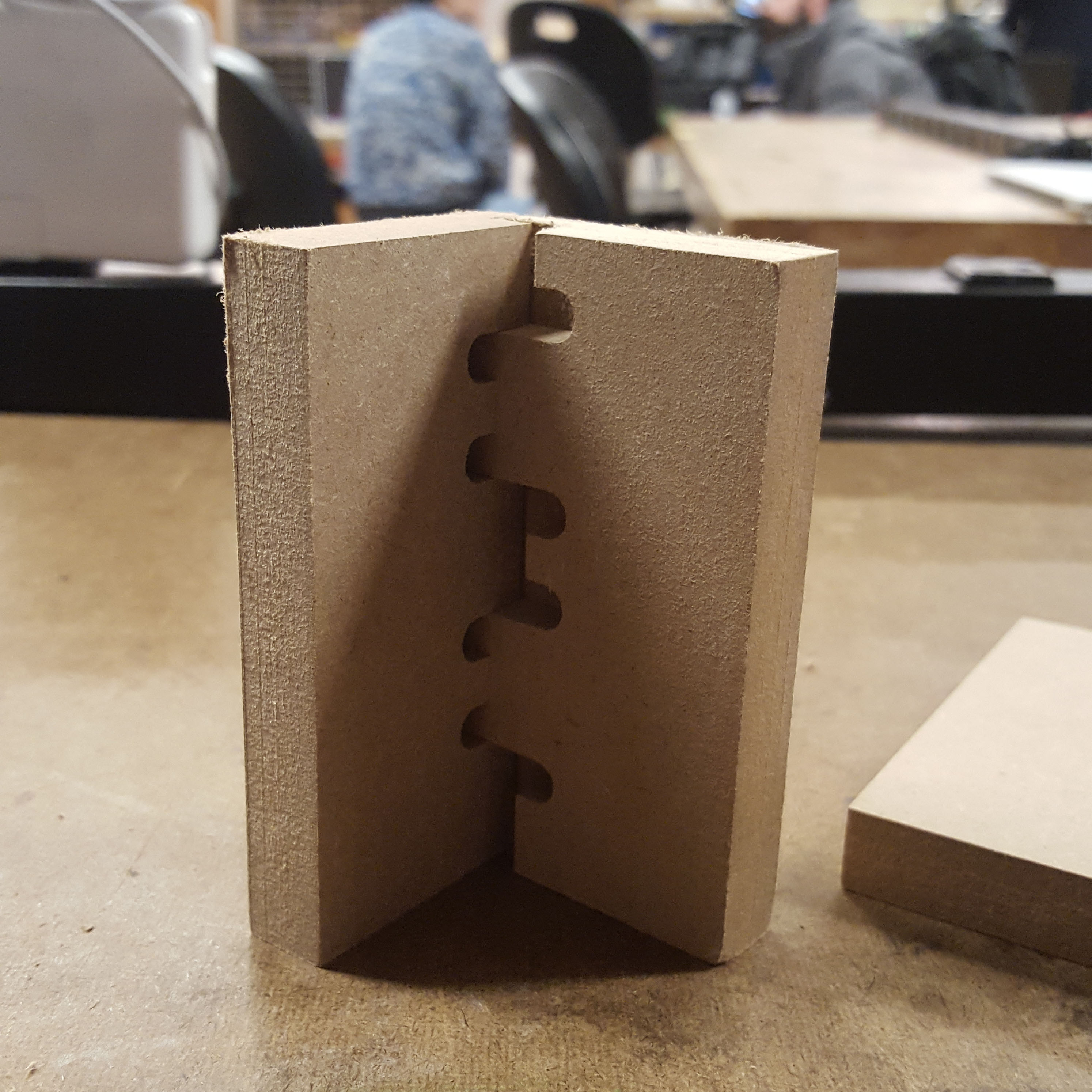

The first version I tried was not quite flush. I had to adjust the spacing of my pocket on the right side.

This one was far more flush, but still had too much of a pocket. Let’s try it again!

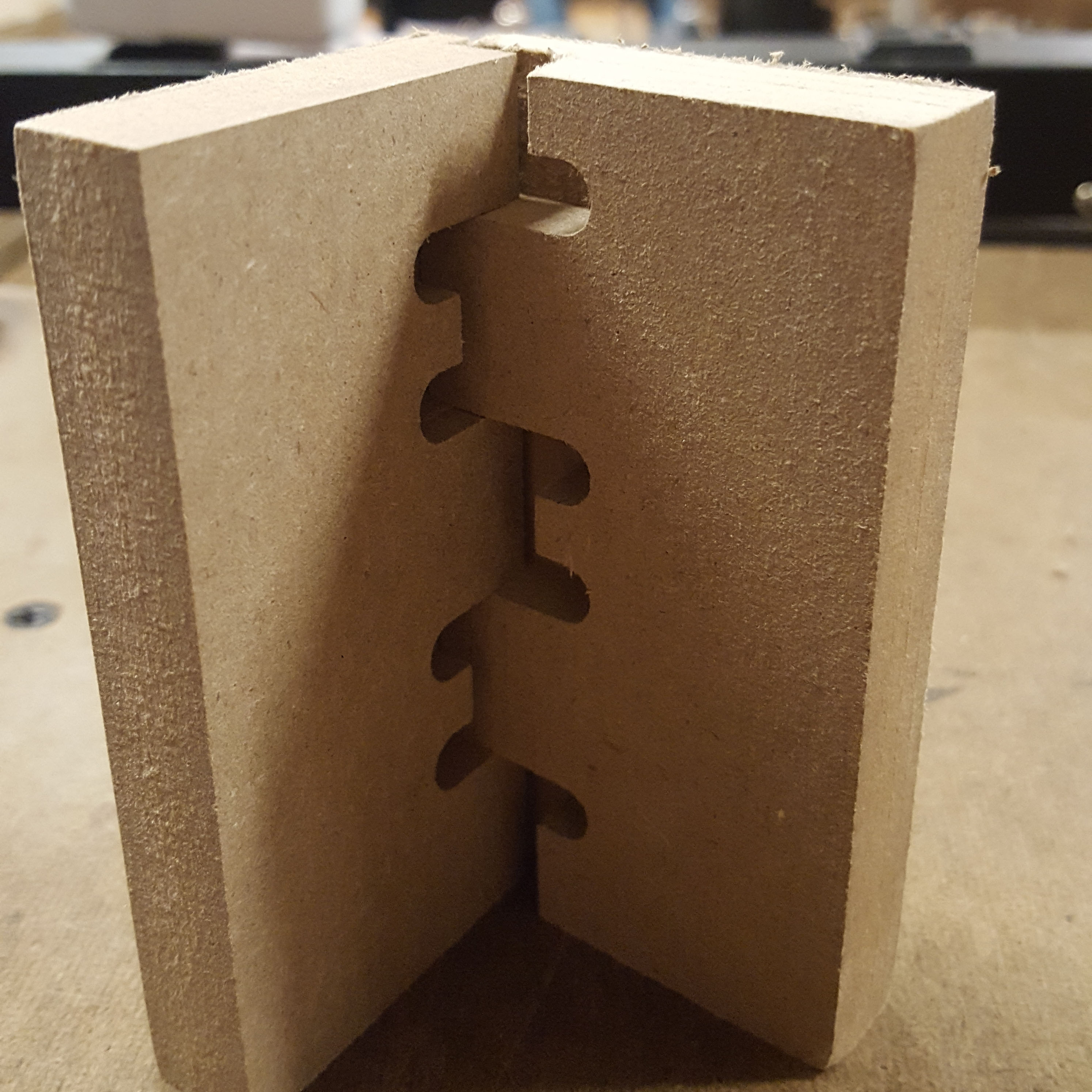

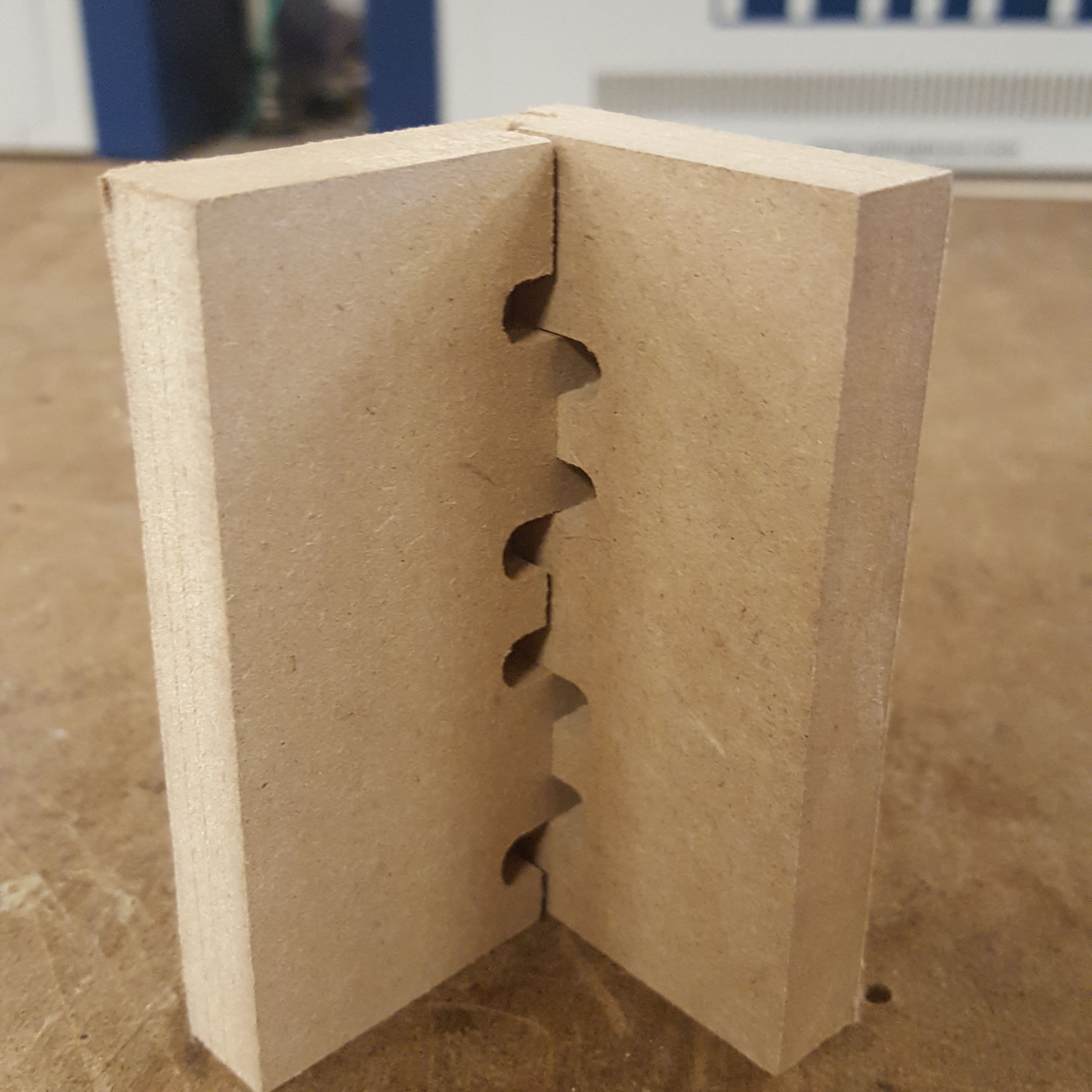

I think this attempt worked out fairly well, and I had run out of my scrap of MDF so I had to stop. It’s pretty nice, though, but I’ll have to try out the joints again when I get my materials for my vending machine. I’ll be ordering ply instead of MDF– what if somebody spills things onto my vending machine– so the material change might make things a little different.

Subscribe via RSS