Prototyping a Vending Machine

As I mentioned in my previous post about Subtraction, I wanted to prototype a Vending Machine housing for my midterm project. It’s a project born out of the Battery Store, a small business run by me and Lindsey Daniels (and a few other helpers!) If you’re at ITP and want cheap batteries, check out the details.

It’s also a part of NYU’s prototyping fund. Perhaps in the future, we’ll make a kitso other popel

I switched to a terrible pine plywood from MDF, because I had run out of MDF– I’m slightly regretting it now that I’m seeing everyone else’s projects and how polished they look! But this is meant to be an initial prototype, and I have a nicer ply for the finished version.

Because I wanted to use what I learned from the last exercise, I used those complicated hidden finger joints on the sides again. Since it was a different material, I tested out the joints again before working on a final copy– a good decision because it took a few tries before I got the joints tight again!

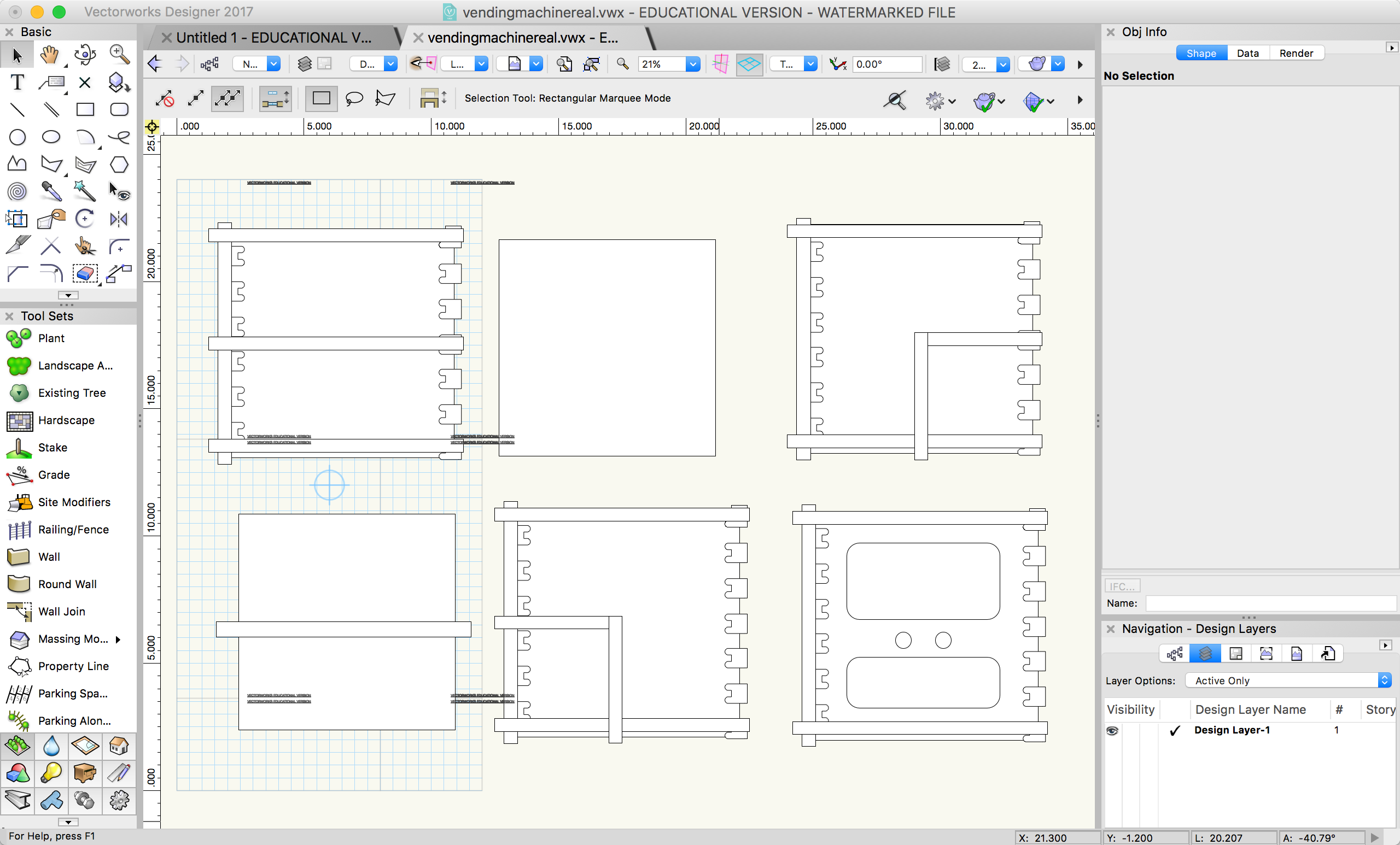

After getting this right, I drew out the vending machine in Vectorworks. Since it’s just a prototype, I planned on only a two-item vending machine, with a shelf to hold the items. I didn’t plan on having the shelf for class, though.

In total, I was on the CNC for around five hours. I feel like I’m an expert on the thing now. Relatively speaking, anyways. Compared to the rest of the first-years, perhaps?

Here’s the completed prototype of the housing. I also tried out the shelf but… I didn’t measure everything quite perfectly. I cut out the shelf before I finished the rest of the housing, which was a mistake. But now that the housing is done, I can work on getting a shelf that fits.

Subscribe via RSS