4-Axis Mill

The lathe was out of service last week, so I had a week off from blogging about Subtraction. The metal lathe was admittedly a bit intimidating, but I had wanted to try it. Oh well! This week, we tackled the 4-Axis mill.

The hardest part of this week’s exercise was working with Vectorworks– my background in no way involves 3D modelling so I had no idea how to work with this software. Photoshop and Illustrator? Fine. But add another dimension and I’m lost. I had to try hard not to compare myself to other people in the class– they have backgrounds in industrial design, I tell myself, so they knew how to model already.

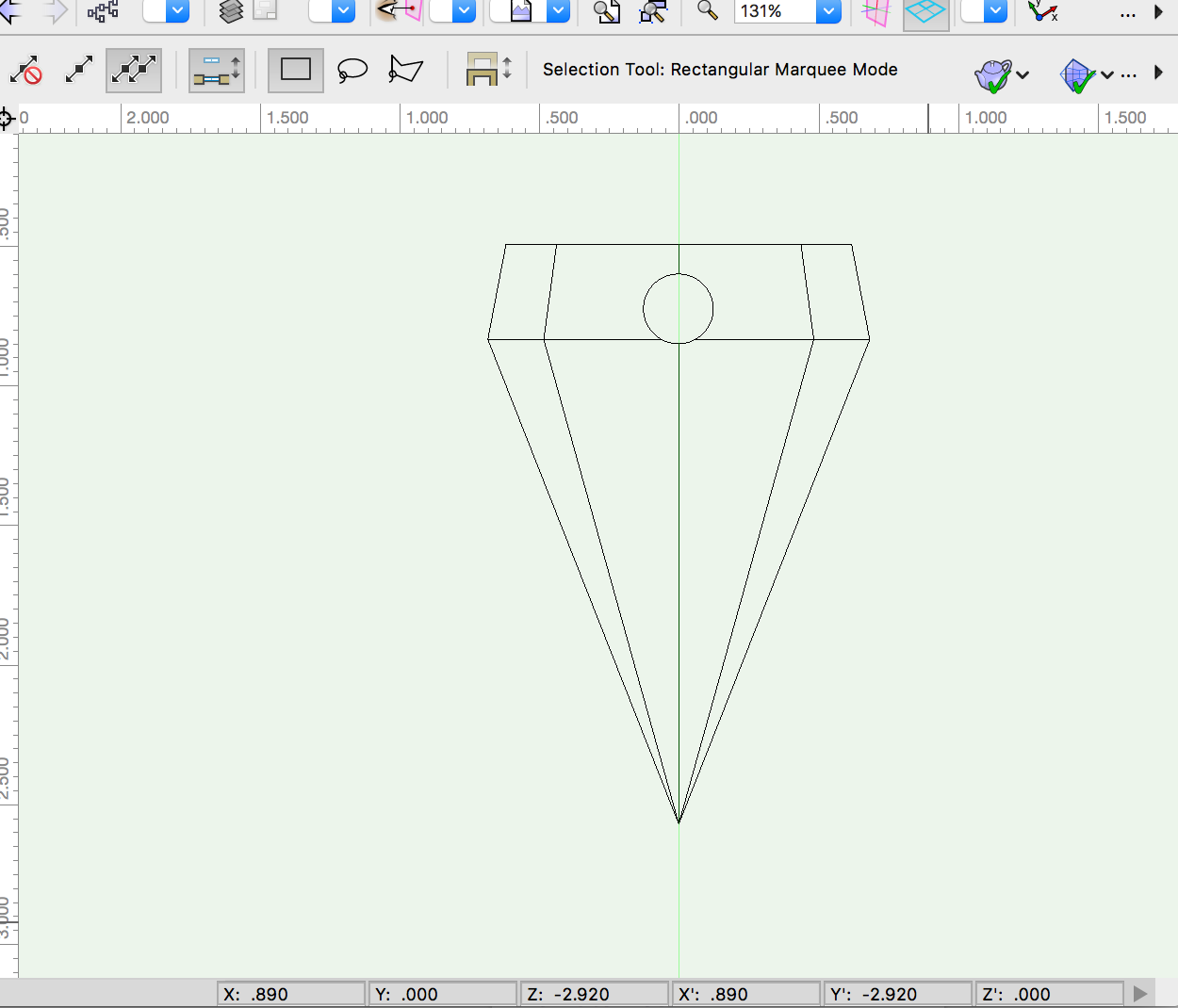

I decided that I wanted to make myself a simple, geometric necklace. It took a while to figure out Vectorworks’ interpretation of “extruding”, but I eventually settled on the folowing shape.

Honestly, I couldn’t quite remember all the steps for setting up the mill, and had to ask Eric for help. He was a great help, but admittedly all I didn’t remember was that I needed an allen key to move the tail stock.

The cut out job took a bit under an hour. Eric had advised me to use a lot of tabs (because he hadn’t, and his project snapped) so it’s a bit bulky and needs to be sanded down.

To my immense regret, though, I cut the thing out without first drilling the hole– so I had to clamp it to drill the hole. After I did so, though, the bottom part snapped off– which isn’t too regrettable, since it still looks more or less like I did so intentionally.

After I finished sanding it down, I took some yarn from the soft lab and threaded it through. It’s alright for a first try at the mill!

Subscribe via RSS